how does a brushless drill motor work

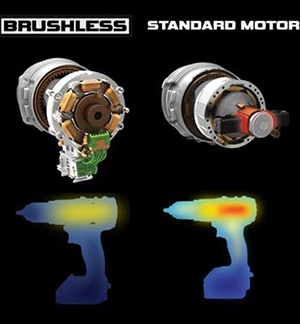

A brushed motor has a relatively simple design and the required parts to make it are much cheaper than the ones required to make a brushless motor. With a brushless motor however we do away with the commutator and brushes and thus the friction generated on a more common motor.

Brushless Vs Brushed Tools Overview Youtube

Brushless design allows for smaller and lighter drills with even more power.

. On the contrary the electronic communicator in brushless motors is a newer technology and hence it is more expensive. To give you an idea a brushless drill costs twice as much as a brushed one. A computer then charges the electromagnets in the stator to rotate the rotor a full 360-degrees.

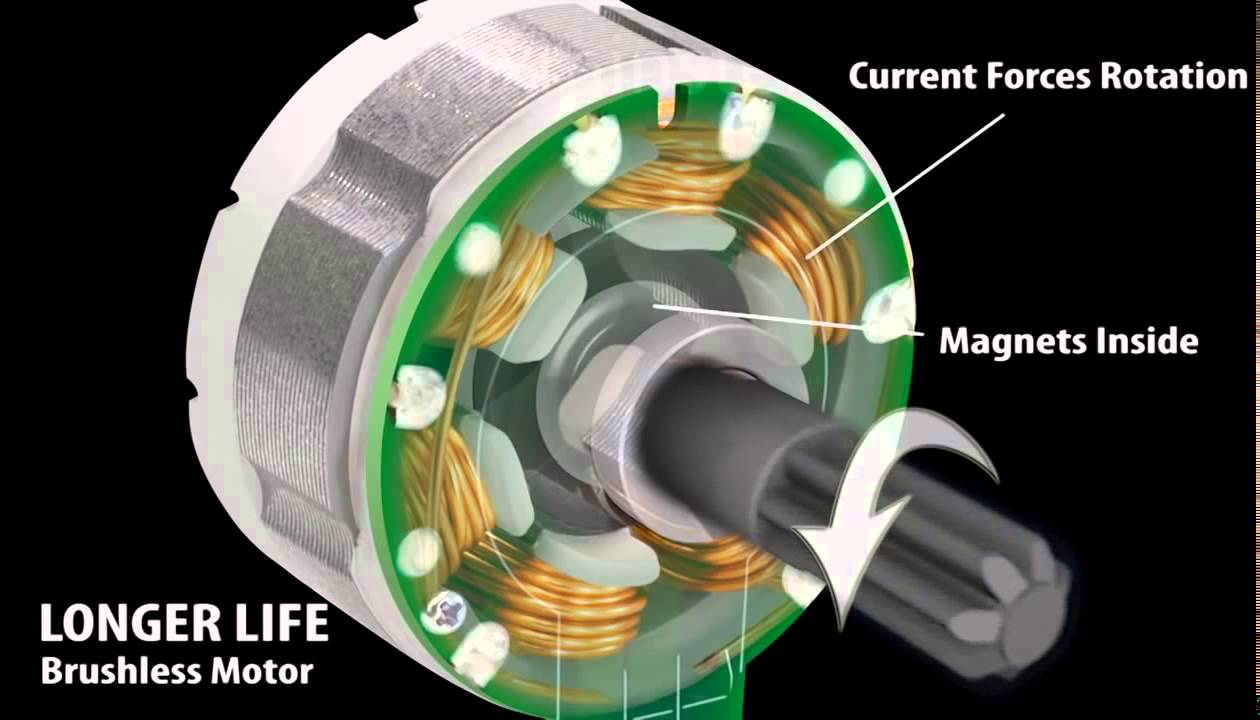

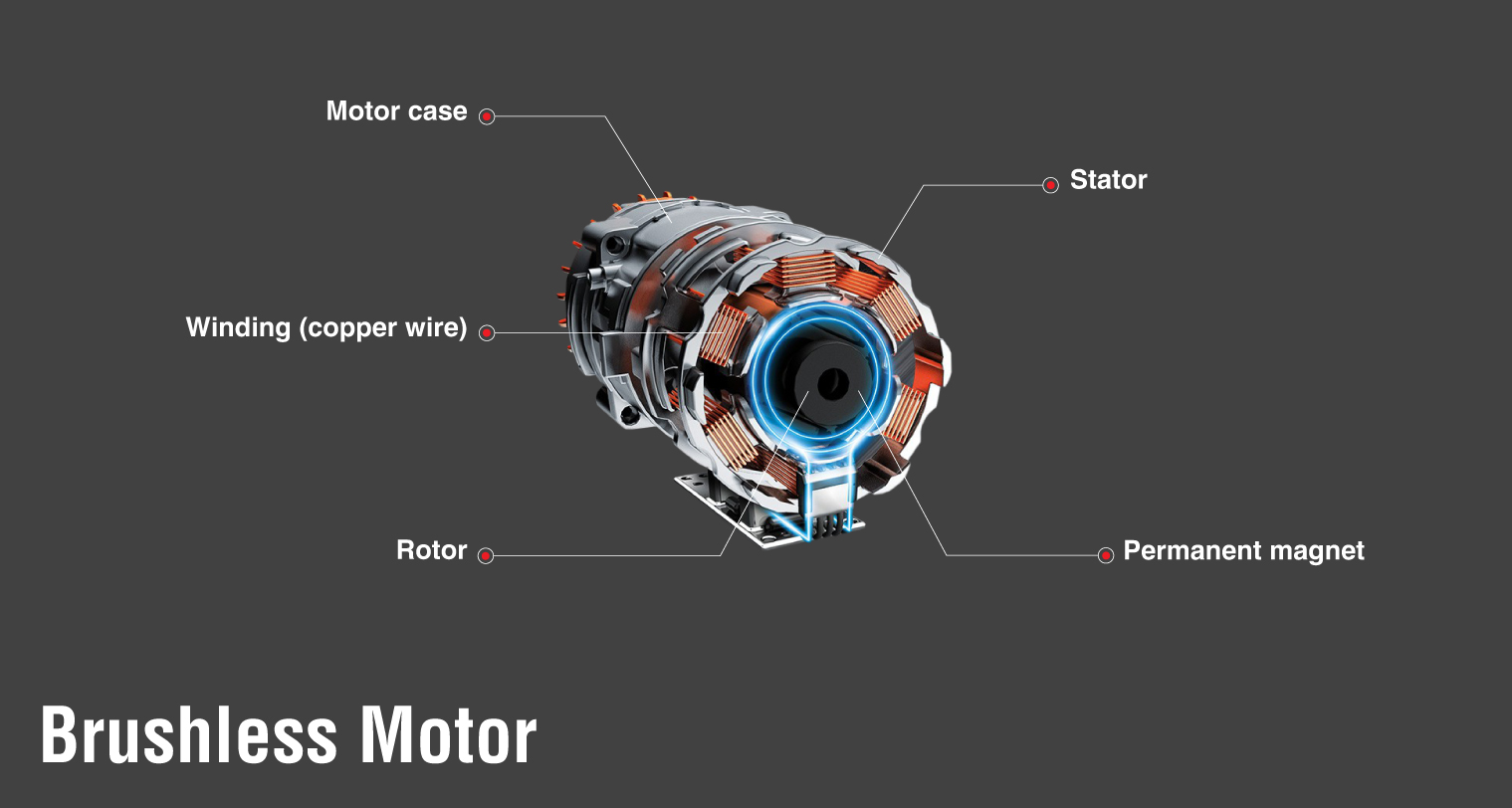

How Does A Brushless DC Motor Work. It increases the devices overall efficiency. Using the three-phase motor as shown in figure below the process starts when current flows through one of the three stator windings and generates a magnetic pole that attracts the closest permanent magnet of opposite pole.

Both brushed and brushless motor assemblies consist of two main components. Like brushed DC motors brushless motors work by alternating the polarity of the windings on the interior of the motor. Although the price is slightly higher but this is a.

The main difference between brushless or brushed drill motors is that the brushed variants are made of carbon while the brushless units use magnets to generate power. Brushless motors are more energy-efficient more responsive and able to pack more power torque and speed. Brushless motors are used in the place of various types of AC motors.

The magnetic fields created when the coils are generated exert a pushpull force on the permanent magnets arranged around the outside of the casing. BLDC Motor operation is based on the attraction or repulsion between magnetic poles. They can reach higher speeds too.

How does a drill motor work. For brushed drills the motor works at full power for each bore hole wasting valuable battery time. Small battery-powered devices use brushless motors to improve the drive efficiency therefore increasing the length of battery life.

How Brushless Motors Work. Brushless drills make use of a brushless motor which is a step up from a conventional DC motor. How Does A Brushless DC Motor Work.

A brushed motor uses brushes and a commutator to supply electricity to the magnetic coils of the armature. The major disadvantage of brushless motors is the cost. This can create friction heat and loss of energy at the point of contact.

Because brushless tools have the current regulated by a circuit board rather than a direct connection a brushless tool will only ever draw the power it needs for the application at hand. If you have to adjust screws in tough places or three or more inches. Less resistance means less friction and it helps to operate the machine efficiently without heating.

And the locations of the magnets and windings are reversed. This is due to the sensors. The magnets are on the conventional motor shaft and the copper windings of the.

Can better prevent dust and debris. How does a brushless drill work. A brushless motor loses the brushes and the commutator.

And the brushless motor is easier to maintain smaller and lighter and the friction-lessness in the brushless bit means less wear and less heat. A brushless motor works through a. The brushed one heated up to about 655 C whereas the brushless one only got to 40 C a 25-degree temperature difference.

Without brushes to cause friction and slow things down brushless drills pack more power and torque. The temperature difference is essential as the more heat your tool has the. A good example is drilling in plaster board.

With the advent of cheap computers and power transistors it became possible to turn the motor inside out and eliminate the brushesIn a brushless DC motor BLDC you put the permanent magnets on the rotor and you move the electromagnets to the stator. A brushless DC motor is essentially flipped inside out eliminating the need for brushes to flip the electromagnetic field. My older brush-type drill same model will drive screws even at.

This is done by the attracting and repelling actions of a magnet that make the shaft spin. In brushless DC motors the permanent magnets are on the rotor and the electromagnets are on the stator. A brushless drill for example might run anywhere from 30 to 50 percent longer than the same cordless drill fitted with a brushed motor.

Then you use a computer connected to high-power transistors to charge up the electromagnets as the shaft turns. The brushless motor will outperform the brush motor when constantly used side by side for 10 minutes each and temperature difference was visible. Capable of packing more power torque and speed.

A computer then charges the electromagnets in the stator to rotate the rotor a full 360-degrees. Brushless motors are more energy-efficient more responsive and able to pack more power torque. Brushless drills do away with carbon brushes running more energy-efficiently and requiring less maintenance due to the fact that there is no need to replace the brushes.

In brushless DC motors the permanent magnets are on the rotor and the electromagnets are on the stator. Whether you need a drill occasionally around the house or every day at work the brushless drill motor provides definite advantages for your needs. It reduces the power required to operate the devices significantly.

On a brushless DC motor it is not the motor shaft that rotates but rather. Because they operate under a different principle compared to brushed motors they tend to cost more. For this reason brushless motors are better adapted generate no friction produce less heating and provide better performance.

My new cordless brushless drill has good torque but it wont turn below about 50 rpm. Advertisement There are other advantages to brushless motors. The main difference between brushed and brushless motor is resistance brushed motor offer more resistance so brushless motor requires little energy to drive screws or drill.

And although this is fantastic news for corded machines for cordless its even more crucial.

Xr Brushless How A Brushless Motor Works Gonefco Com Youtube

What S The Difference Between Brushed Vs Brushless

Brushed Vs Brushless Motors How They Impact Your Power Tool S Performance Ibt Industrial Solutions Ibt Industrial Solutions

Brushless Vs Brushed Motors In Cordless Tools Ronix Blog

Brushless Vs Brushed Motor Why You Should Know The Difference Cdz

What S The Difference Between Brushed Vs Brushless

Dewalt Xr Brushless How A Brushless Motor Works Youtube

How It Works Electic Motors Electric Motor Electric Generator Electricity

Brushless Vs Brushed Drill Exhaustive Facts And Faqs

What S The Difference Between Brushed Vs Brushless

Why Are Brushless Drills Better Than Brushed Drills

How To Make Brushless Electric Drill Youtube

What Is A Brushless Drill Mechanicwiz Com

Makita Dlx2002m Brushless Motors Youtube

Brushless Vs Brushed Motors In Cordless Tools Ronix Blog

Brushless Vs Brushed Motor Why You Should Know The Difference Cdz

Brushless Motors Understanding The Current Evolution In Cordless Power Tools